A glass manufacturing client was experiencing difficulty with high water hardness in the RO permeate. FEDI was chosen to overcome this challenge as Fedi is able to treat water up to 3ppm as CaCO3, unlike the conventional EDI systems.

A global glass manufacturer, with facilities located in India, needed high purity water for their boiler application (steam production). This client wanted to keep their process to a single process RO rather than moving to a dual pass system and incurring additional cost. The solution was found in QUA's Fractional Electrodeionization (FEDI), a robust equipment that is uniquely capable to address hard to treat water. FEDI uses dual voltage technology to address high hardness water and adapts to varying source water conditions.

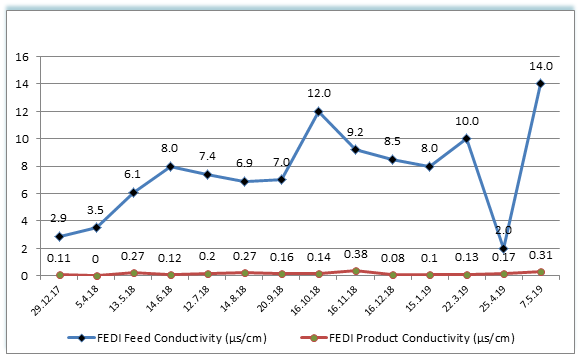

The FEDI system has been in place for 3 years at a flow rate of 12m3/hr, performing consistently for the client with no need for replacement or repair.

The client has approved FEDI's performance and issued a letter of appreciation, which only goes on to cement QUA's leadership position in the advanced membrane products market.

- FEDI can operate with the challenging single-pass RO permeate. The client was thus able to save on the cost of a second pass RO, which they would have incurred with any another EDI system.

- The FEDI system has been in continuous operation since commissioning, and is delivering consistently superior product water quality with low conductivity, of less than 0.5 microS/cm, to be used as boiler feed.

- These EDI units have not required any chemical cleaning during the years of operation on account of hardness scaling, and have been operating without interruption.