“We went in for a retrofit of existing UF due to off the shelf availability of QUA membranes and their technical support. But what we got in return was net savings, in addition to consistent permeate quality. This finally paved the way for QUA membranes for our future projects”…. S. Anand, Director, AquaMatrix

Q-SEP Model: Q-SEP® 4508Total Q-SEP Membranes: 7

Permeate Flow: 15m3/hr

Application: Automotive component plant effluent treatment

An auto ancillary plant in Chennai, India was in need of a new pretreatment system for their effluent treatment plant (ETP). The client had installed an ETP to treat the wastewater generated from their auto ancillary unit. The ETP provides complete pretreatment along with biological treatment. However, the ultrafiltration membranes were not able to perform due to challenging feed parameters which caused rapid fouling and required frequent cleaning. This problem hindered production for the client so they looked to QUA for a speedy and reliable solution.

The end user’s UF plant was configured with another manufacturer’s inside/out PES membranes. Though the plant had been running for the past one year, the UF membranes were not able to perform due to challenging feed parameters. This resulted in a faster than expected rise in Transmembrane pressure (TMP). The membranes began fouling quickly and frequent chemical cleaning (CIP) was required for the UF and RO systems. The membranes were unable to adequately pretreat the water and meet the expected performance criteria, and required replacement.

QUA Solution

Client selected Q-SEP because of its low fouling characteristics, uniform pore size distribution and large surface area. QUA also assured delivery within a week’s time, to fulfil the client’s urgent requirement.

Q-SEP 4508 model was able to replace the existing UF without any hassle and without incurring heavy costs. Q-SEP was longer than the current UF modules by 72mm and thus required header replacement. However, instead of replacing the entire header, only the top permeate header was elevated to suit the height requirement. This was simple and the client was able to save on the additional costs, which they would have incurred otherwise for replacement of UF. They were able to avoid CIP downtime cost as Q-SEP were delivered immediately.

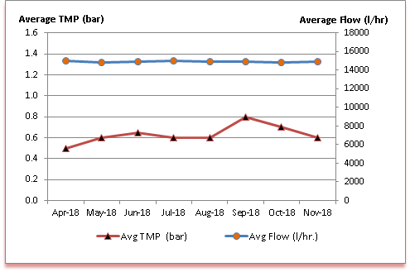

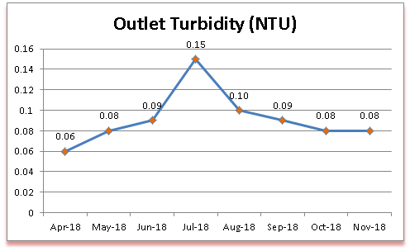

Q-SEP 4508 membranes have been working satisfactorily since then, meeting all performance criteria. The system is able to provide a consistent permeate output of 15 m3/hr with

- TMP consistently between 0.5 – 0.8 bar

- SDI at the outlet of Q-SEP less than 2, 100% of the time.

To read more or download visit:Here