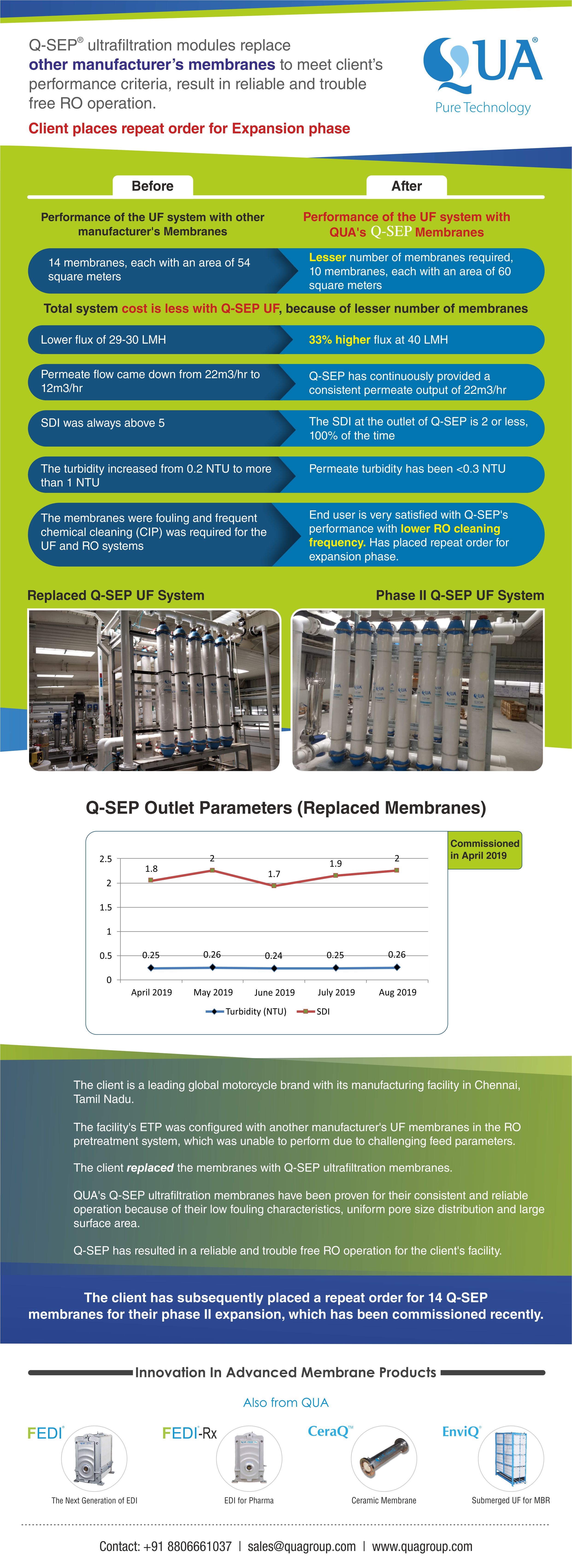

The client, one of the best known medical care services brand in India, was installing a sewage treatment system to treat hospital sewage. They wanted to recycle and reuse the treated sewage water for cleaning, flushing and gardening. Ultrafiltration was chosen as pretreatment to the reverse osmosis system. The UF feed water was tertiary treated hospital waste. The customer had stringent quality standards, and was searching for a reliable and advanced ultrafiltration solution, which would not choke and foul repeatedly.

Looking for nothing but the best, the client considered various options and finally selected QUA’s Q-SEP inside-out UF membranes. The client was convinced by the differentiating factor between Q-SEP and other membranes being offered was that Q-SEP membranes are manufactured with QUA’s innovative and patented “Cloud Point Precipitation” method, which ensures.

- a high pore density along the length of the fiber and uniform pore size distribution in the membrane

- 95% of the pores are of the size 0.02 micron.

- Q-SEP modules are extremely effective even in challenging effluents, and deliver superior performance characteristics and product water quality that surpass the quality from conventional UF modules.

- excellent rejection of bacteria and viruses

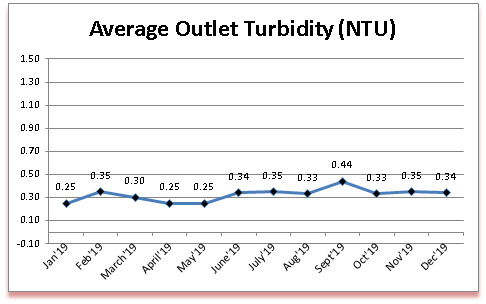

The Q-SEP system at the hospital sewage recycle plant has been operational since June 2014 now. The UF is able to provide a Consistent Permeate output of designed capacity, and the hospital sewage is being successfully treated without any significant rise in the trans membrane pressure. Client has been getting consistent product water quality of SDI less than 3 and turbidity less than 0.5, which they are using very effectively.

Find out more about Qsep® Here